Top 10 Benefits of Using Gravel Geogrid in Construction Projects?

In the realm of construction, efficiency and durability are paramount. Gravel Geogrid has emerged as a transformative material. This innovative solution enhances stability in various construction projects. It offers notable benefits, especially for road and foundation works.

Using Gravel Geogrid can significantly reduce costs. Traditionally, projects require more soil and aggregate. With this geogrid, less material is needed. It improves load distribution effectively. This material is not just cost-efficient but also strengthens structures. However, its application can be misjudged. Proper installation is crucial for achieving desired results.

Many contractors overlook maintaining the right tension during installation. This can lead to uneven surfaces, prompting costly repairs later. Awareness of these details can make a significant difference. In essence, Gravel Geogrid is a game-changer. Yet, it requires careful consideration and expertise to maximize its potential.

Overview of Gravel Geogrid Technology in Construction

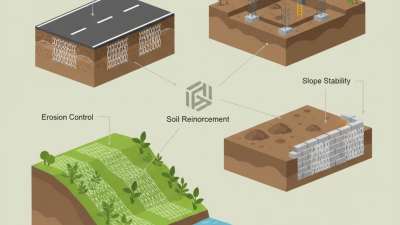

Gravel geogrid technology has emerged as a significant innovation in construction. It provides a robust solution for stabilizing soil and controlling erosion. This approach uses a grid-like structure made from synthetic materials. This allows for better load distribution in the soil, which leads to enhanced stability for various projects.

This technology stands out due to its lightweight nature. It is easy to transport and install. Construction teams appreciate this convenience, yet poor installation can lead to issues. When placed incorrectly, the benefits diminish, causing potential project delays. Regular monitoring is crucial to ensure continued effectiveness. Contractors must train their teams thoroughly to reap the full benefits of gravel geogrids.

Additionally, gravel geogrids promote better drainage, reducing water pooling. This feature enhances the lifespan of roadways and foundations. However, relying solely on this technology without proper site assessment can be a mistake. Each site is unique, and a one-size-fits-all approach may be ineffective. Thoughtful planning and site evaluation remain essential in leveraging gravel geogrids properly.

Top 10 Benefits of Using Gravel Geogrid in Construction Projects

Improved Load Distribution and Stability with Gravel Geogrids

Gravel geogrids have emerged as a popular choice in construction projects. They enhance load distribution and stability across various types of surfaces. The grid structure allows soil and gravel to interlock, which significantly improves overall support. When heavy loads are applied, these geogrids help to spread the weight over a larger area. This can prevent the typical sinking or shifting that occurs with conventional methods.

Using gravel geogrids also promotes drainage. Water can easily flow through the grid, reducing the risk of erosion. This is essential in areas prone to heavy rainfall. Moreover, proper water management supports the durability of the construction. A well-drained site is less likely to experience damage from freeze-thaw cycles or water stagnation.

Tip: Ensure proper installation of the geogrids. Inadequate placement may lead to insufficient load distribution. Pay attention to the soil preparation before installation. Clearing debris and compacting the soil can enhance the geogrid's effectiveness. Remember, even the best materials require careful handling. Regular maintenance can also prolong the life of the structure.

Enhanced Drainage and Erosion Control in Construction Sites

Gravel geogrid plays an essential role in enhancing drainage at construction sites. Effective drainage prevents water accumulation, which can weaken foundations. Without proper drainage, erosion becomes a major concern. Erosion may lead to costly repairs and safety hazards. Gravel geogrids can direct water flow, allowing it to drain efficiently.

Incorporating gravel geogrids aids in controlling soil erosion. The grids create a stable layer that holds soil particles in place. This stability minimizes the risk of washing away during heavy rains. However, it’s crucial to install these geogrids correctly. Mistakes in placement can lead to unwanted settling or uneven surfaces. Regular inspection is necessary to maintain their effectiveness over time.

While many construction managers appreciate the benefits, some overlook minor details during installation. These oversights can impact drainage performance. Continuous monitoring ensures that the system remains functional and effective. In the long run, this attention to detail can save resources and time. Investing in gravel geogrids is a step toward sustainable site management.

Top 10 Benefits of Using Gravel Geogrid in Construction Projects

| Benefit | Description | Impact | Cost Efficiency |

|---|---|---|---|

| Enhanced Drainage | Gravel geogrids improve water flow through soil. | Reduces waterlogging issues. | Lower maintenance costs. |

| Erosion Control | Prevents soil displacement. | Maintains landscape integrity. | Decreases restorative expenses. |

| Load Distribution | Distributes weight across a larger area. | Enhances stability under heavy loads. | Lowers repair and reinforcement costs. |

| Increased Lifespan | Reduces material degradation. | Extends the life of construction sites. | Decreased replacement expenses. |

| Environmental Sustainability | Utilizes natural materials effectively. | Reduces carbon footprint. | May lead to tax incentives. |

| Rapid Installation | Quicker setup than traditional methods. | Decreases project timelines. | Saves labor costs. |

| Versatility | Applicable in various terrains. | Adapts to different project requirements. | Reduces need for multiple products. |

| Cost-Effective | Low initial investment. | High return on investment over time. | Limits overall project expenses. |

| Improved Aesthetic | Enhances visual appeal of project sites. | Attracts positive attention. | Can increase property value. |

| Safety Enhancements | Lowers risk of soil collapse. | Increases site safety for workers. | Potential reduction in liability costs. |

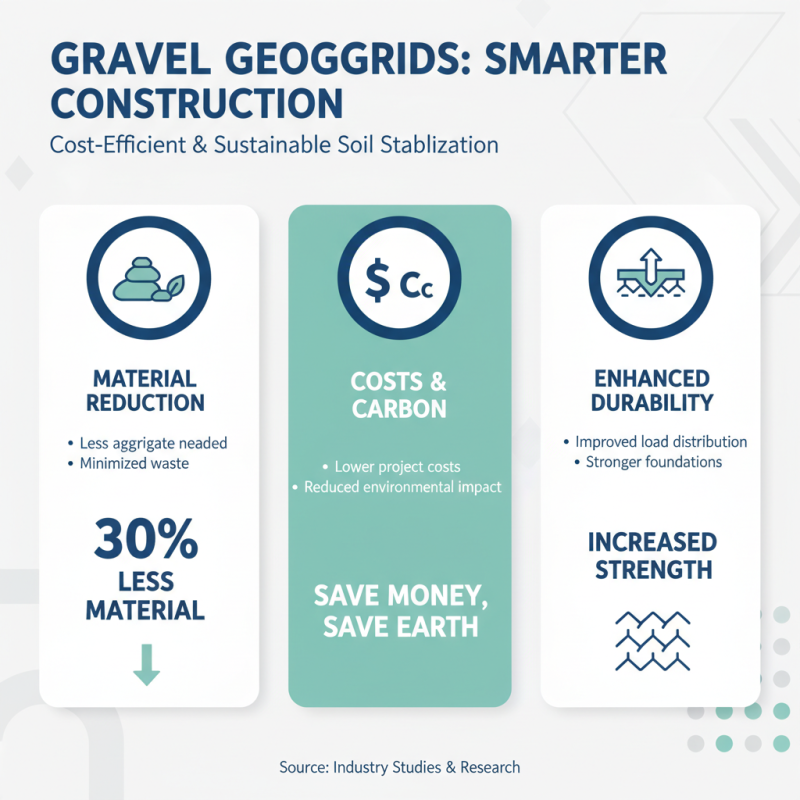

Cost Efficiency and Sustainability of Using Gravel Geogrids

Gravel geogrids have gained attention in construction due to their cost efficiency and sustainability. Studies show that utilizing gravel geogrids can reduce material usage by up to 30%. This not only lowers costs but also minimizes the carbon footprint. In projects where soil stabilization is crucial, gravel geogrids enhance load distribution. This means fewer materials are needed to achieve durability.

Sustainability is another aspect of gravel geogrids. According to a report by the International Journal of Geosynthetics, using these geogrids can lead to a decrease in the need for excavation. This is beneficial for the environment and reduces the disruption to existing ecosystems. Moreover, gravel geogrids are made from recycled materials, which supports a circular economy in construction.

Despite these advantages, it is important to consider the long-term performance and maintenance of gravel geogrids. While they are effective, some projects may face challenges, such as soil erosion or improper installation. Data suggests that maintenance costs could arise after several years if not done correctly. Addressing these issues requires thorough planning and knowledge.

Applications and Case Studies of Gravel Geogrid in Projects

Gravel geogrid has garnered attention in construction projects for its numerous applications. In one study, it was reported that the use of geogrids can reduce the aggregate thickness by up to 50%. This leads to significant cost savings and a lighter foundation. Geogrids create a stable platform, allowing for proper load distribution. This can be crucial in heavily trafficked areas, such as highways and airports.

In recent case studies, gravel geogrids have been integrated into road construction. One project noted a 30% reduction in maintenance costs over five years. Moreover, another study highlighted how geogrids amplified the lifespan of gravel surfaces by twofold. These results demonstrate their effectiveness in enhancing the resilience of infrastructure. However, some projects faced challenges with installation quality, leading to inadequate performance. Addressing such concerns is vital for optimizing their benefits.

Overall, the advantages of gravel geogrid are clear, yet it's essential to monitor application processes. Ensuring proper installation is crucial for achieving the desired durability and cost-effectiveness. With careful attention to detail, the full potential of gravel geogrids can be realized in various construction scenarios.

Related Posts

-

Why Choose Geogrid Fabric for Your Construction Projects?

-

Best Cirtex Geogrid Applications for Soil Stabilization and Erosion Control

-

Exploring Market Trends: Plastic Geonet Innovations at the 138th China Import and Export Fair 2025

-

Top 5 Benefits of Using Cement Blankets for Construction Projects

-

Why Geotex Textiles Are Revolutionizing Sustainable Materials in Modern Industry

-

2025 Top 10 Benefits of Using Geogrid Paving for Sustainable Construction Solutions

-

Phone

-

E-mail

-

Whatsapp

-

Top