How to Choose the Right Woven Geofabric for Your Project Needs

When embarking on a construction or landscaping project, selecting the appropriate materials can significantly influence the outcome and longevity of the endeavor. One such critical material often overlooked is woven geofabric. As John Smith, a leading expert in civil engineering and geosynthetics, aptly states, "The choice of woven geofabric can make or break the integrity of a project." This underscores the importance of understanding the various options available and their specific applications.

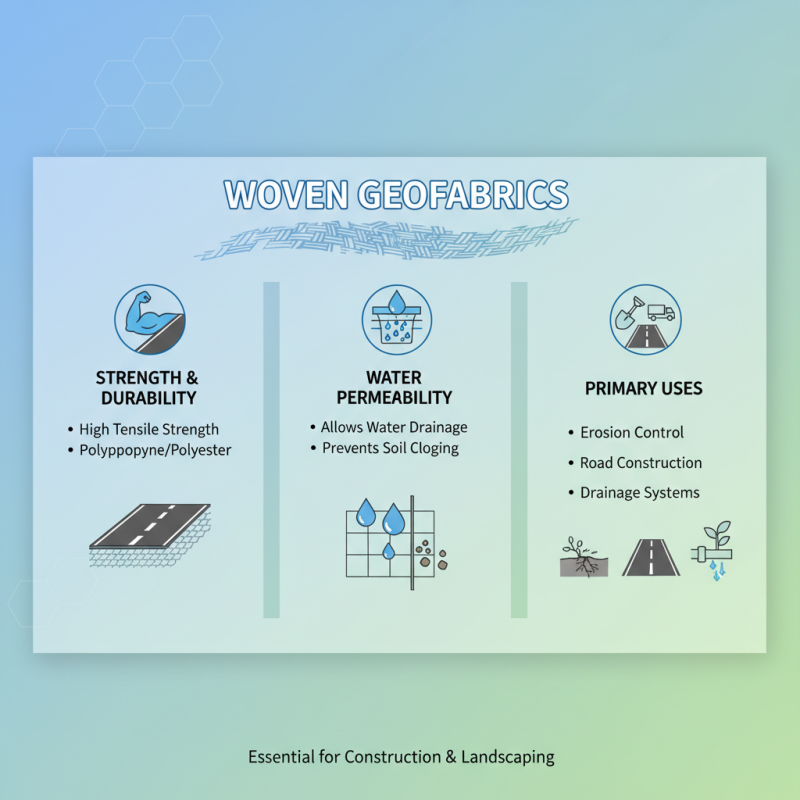

Woven geofabric, known for its strength and durability, serves multiple functions, including separation, reinforcement, filtration, and drainage. Choosing the right type requires careful consideration of the project’s specific requirements, soil conditions, and environmental factors. A well-informed selection not only promotes structural stability but also enhances the overall efficiency of drainage systems and erosion control measures.

In this guide, we will explore the essential factors to consider when selecting woven geofabric for your project needs. By understanding the various types and their properties, you can make an informed decision that will not only meet the demands of your project but also contribute to its sustainable success.

Understanding Woven Geofabrics: Types and Applications

Woven geofabrics are essential materials used in various construction and landscaping projects, mainly for their strength and versatility. Typically made from woven polypropylene or polyester, these geofabrics offer excellent tensile strength and durability, making them suitable for applications such as erosion control, road construction, and drainage. One of the key advantages of woven geofabrics is their ability to allow water to drain while preventing soil particles from passing through, which is vital in maintaining the integrity of soils in a range of environments.

Different types of woven geofabrics serve specific functions depending on the project's needs. For instance, lightweight woven fabrics are ideal for applications like mulch stabilization, where they help retain moisture and support plant growth. Conversely, heavier geofabrics are better suited for heavier loads and reinforcing structures, such as retaining walls and slopes, where soil stabilization is crucial. Understanding the specific characteristics and applications of various woven geofabrics will ensure the right selection for your project, ultimately impacting its success and longevity.

Key Factors to Consider When Selecting Woven Geofabric

When selecting woven geofabric for your project needs, several key factors come into play that can impact both the performance and longevity of your installation. Firstly, understanding the specific application is crucial. Woven geofabric can be used for erosion control, drainage, reinforcement, or separation. Each application will require different specifications in terms of strength, permeability, and durability. It's essential to evaluate the environmental conditions the geofabric will be exposed to, such as soil type, moisture levels, and potential loads, as these influences will dictate the best choice for your project.

Another important consideration is the material composition of the woven geofabric. Most commonly made from polypropylene or polyester, the choice of material can significantly affect the geofabric’s resistance to UV rays, chemical exposure, and mechanical stress. Higher quality geofabrics offer improved performance and longevity, making them a worthwhile investment in the long run. Additionally, evaluating the fabric's tensile strength and tear resistance is vital to ensure that it can withstand the specific stresses it will encounter in your application. By taking these factors into account, you can make a more informed decision that aligns with your project goals.

Evaluating Woven Geofabric Performance and Durability

When selecting woven geofabric for your project, understanding its performance and durability is essential. Woven geofabrics are designed to provide structural support and separation in various applications such as road construction, erosion control, and drainage solutions. Factors like tensile strength, puncture resistance, and UV stability significantly influence their overall performance. A geofabric with high tensile strength will withstand stress and deformation better, making it ideal for heavy loads or unstable ground conditions. Additionally, assessing the material's puncture resistance ensures longevity, especially in scenarios where sharp objects may be present.

Tip: Before finalizing your choice, conduct a field test if possible. This can help you observe how the geofabric behaves under actual conditions, providing insight into its performance over time.

Durability is another critical aspect. Woven geofabrics should exhibit resistance to environmental factors such as moisture, temperature fluctuations, and biological deterioration. Products that perform well in adverse weather and resist degradation can save time and costs associated with maintenance and replacements. Furthermore, consider the expected lifespan of the geofabric in relation to your project timeline.

Tip: Look for geofabrics that offer product warranties or certifications. These can serve as indicators of quality and can provide peace of mind regarding the longevity of your investment in woven geofabric solutions.

Cost Analysis: Budgeting for Woven Geofabric Projects

When budgeting for woven geofabric projects, understanding the cost factors involved is crucial for effective financial planning. Woven geofabrics can vary significantly in price based on their material composition, tensile strength, and intended application. It's essential to analyze your project's specific needs carefully. For instance, a geofabric used for erosion control may require a different grade compared to one designed for reinforcement in road construction. This variation in requirements can lead to different cost implications, making it vital to align your material choice with the project's goals.

Tips for budgeting effectively include obtaining multiple quotes from suppliers to compare prices and terms. This can help you identify market trends and ensure you're getting the best value for your investment. Additionally, consider the lifecycle cost of the geofabric; sometimes, a higher upfront cost can lead to lower maintenance expenses over time. Finally, don't underestimate the importance of planning for contingencies, such as unexpected site conditions or project delays, which may affect overall costs.

Moreover, be open to exploring alternatives or hybrid solutions in woven geofabric materials that might offer superior performance at a lower cost. Engaging with experts in geotextiles can provide insights into optimal choices that meet your specifications while staying within budget constraints. By carefully analyzing both the immediate and long-term financial ramifications, you can make a well-informed decision that enhances your project's success.

How to Choose the Right Woven Geofabric for Your Project Needs - Cost Analysis: Budgeting for Woven Geofabric Projects

| Project Type | Woven Geofabric Type | Material Cost per Square Yard ($) | Labor Cost per Square Yard ($) | Total Cost per Square Yard ($) | Project Size (Square Yards) | Total Project Cost ($) |

|---|---|---|---|---|---|---|

| Road Construction | Heavy Duty Woven Geofabric | 2.50 | 1.00 | 3.50 | 500 | 1,750.00 |

| Landfill Cover | Lightweight Woven Geofabric | 1.75 | 0.75 | 2.50 | 1000 | 2,500.00 |

| Erosion Control | Standard Woven Geofabric | 2.00 | 0.50 | 2.50 | 750 | 1,875.00 |

Best Practices for Installing Woven Geofabric Effectively

When installing woven geofabric, proper preparation and technique are crucial to ensure optimal performance and longevity. Start by assessing the project site to understand the soil type and the specific drainage and stabilization needs. It's essential to clear the area of any debris, vegetation, and sharp objects that could damage the fabric. Using a level surface can help achieve better results, as uneven ground may lead to challenges in the fabric's effectiveness.

Once the site is prepped, roll out the woven geofabric, ensuring that it overlaps any seams by at least 12 inches to prevent soil loss and deterioration. It’s important to secure the fabric in place using stakes or pins at regular intervals, particularly in windy conditions. After laying the fabric, backfill it with the appropriate materials, such as gravel or soil, making sure to avoid tearing or bunching the fabric. Properly distributing the weight and ensuring that the material used for backfilling is compatible with the geofabric will enhance drainage and stability in the long run. Always follow industry guidelines for specific installation methods based on the project's requirements to maximize the benefits of the woven geofabric.

Related Posts

-

The Ultimate Guide to Understanding Geotextile Mats and Their Impact on Environmental Protection

-

Exploring Innovations in Gsm Geotextile at the 2025 China Import and Export Fair

-

Maximizing Durability and Efficiency of Landscape Projects with Innovative Geotextile Use

-

Exploring the Environmental Benefits of Geotextile Mats in Modern Construction

-

Unlocking the Power of Geotextile Tape: 5 Key Benefits Backed by Industry Trends and Research Data

-

Exploring the Benefits of Woven Geofabric in Sustainable Construction Practices

-

Phone

-

E-mail

-

Whatsapp

-

Top